production...

Leather made by Ecopell promotes nature’s comfort. Ecopell’s origin is natural from the very beginning.

Consequently the carreer of Ecopell starts in production places near our facilities: Mostly under the open sky on the lush meadows of the Alpine foothills – Bavarian nature is unique and unlike anywhere else in the world.

Quality

Splitting

Pretanning

Coloring

qualität

Immediately after their arrival the fresh raw hides are inspected thoroughly, their provenance and condition being scrutinized. Afterwards the hides are put into the “soak pit“ where they are carefully cleaned of the remaining manure and dirt.For more information about natural marks, visit www.natural-marks.com

Incoming inspection of raw materials according to the following criteria:

- fresh goods (not salted)

- LOSE

- scent: normal

- Temperature: 7.2 / 4.3 / 5.6 / 6.3 ° C in the delivered condition

In the lime pit the hair is pared off. The structure of the skin is gently loosened with chalk, sodium sulfide and enzymes in the low-sulfide lime pit. Now the hair can be gently but completely removed and finally deposed off without problems.

Splitting

From this production step onwards the hides are called smoothed skins by experts. Again they are checked individually for their aptitude to become a premium Ecopell product. To obtain nappa leather of the desired thickness the smoothed skins are skived masterly and with utmost care parallel to the surface. By neutralization the pH-value of the smoothed skin is prepared using carbon dioxide and ammonium sulphate.

Mordanting

Enzymes break up the skins for better absorption of the pretanning agents.

Pickling process

To increase the adhesiveness of the pretanning agents the skins are treated with salt, sulfuric and formic acid.

Pretanning

By using glutardialdehyd Ecopell gets its unique softness. The substance is united with the skin in such a way that it can’t be detected afterwards. In addition sodium bicarbonate (also known as baking soda) is employed to regulate the pH-value.

Tanning

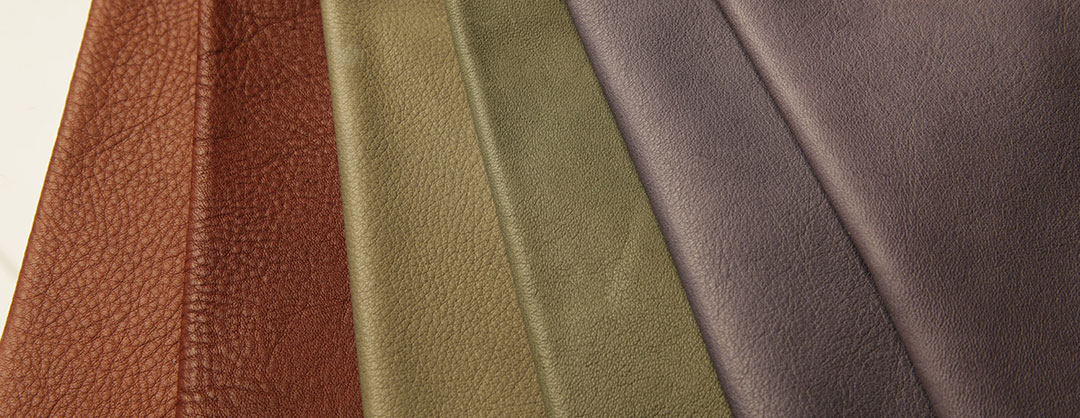

For all dyed Ecopell leathers powder extract made of tarashells is used. Like this we use the trumps of nature. To gain an even grain pattern and regular distribution of the vegetable tanning agents in the skin a low portion of synthane as auxiliary tanning agent is added.

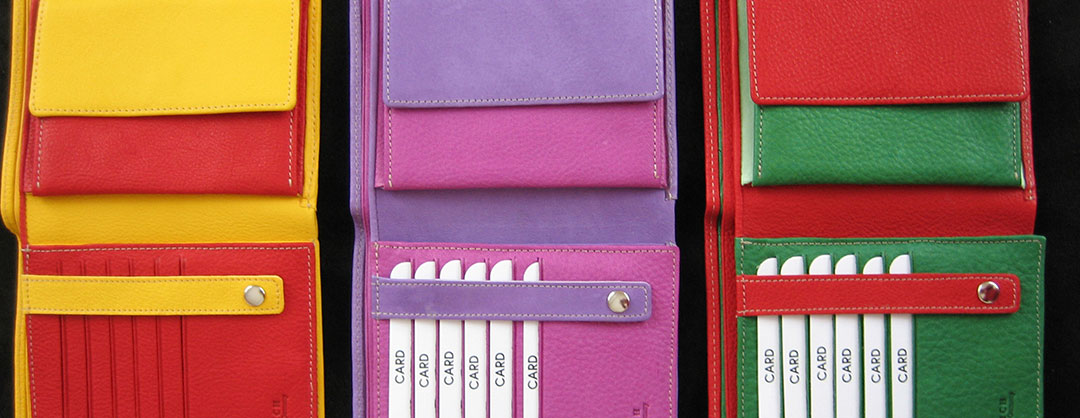

Coloring

In the following dyeing and fatting process again Ecopell GmbH does everything to make sure that genuine leather remains a noble and harmless natural product: Together with formic acid and other acid dyestuff free from heavy metals the dyes and fats are added to the tanning liquor. This way the leather is dyed and thoroughly oiled under continuous control.